Pressure tubes: The heart of the reactor

CNSC response to findings of elevated hydrogen equivalent concentration in pressure tubes operating beyond 210,000 equivalent full-power hours

On July 13, 2021, the CNSC issued formal notices to all nuclear power plant licensees in Canada, requesting further analysis on the continued safe operation of pressure tubes. This was due to Bruce Power finding elevated hydrogen equivalent concentration (Heq) in the pressure tubes of 2 units, in a small region at the outlet end of the tube near the end fitting . The finding only impacted reactors with pressure tubes operating beyond 210,000 equivalent full-power hours (EFPH). This regulatory action was followed by the issuance of orders to Bruce Power and Ontario Power Generation (OPG) on July 26, 2021 and July 27, 2021, to ensure that any reactor in extended operation that had been shut down was not restarted until authorized them by the Commission.

Read the orders:

- Regulatory action – Bruce Power

- Regulatory action – OPG DarlingtonNuclear Generating Station

- Regulatory action – OPG Pickering Nuclear Generating Station

Commission decisions:

- March 28, 2022: Record of decision – Bruce Power – Request for authorization to restart Bruce Nuclear Generating Station A Unit 4 and Bruce NGS B Units 5,7 and 8 following future outages

- February 16, 2022: Record of decision – Ontario Power Generation - Request for authorization to restart Pickering Nuclear Generating Station B Units 6-8 following future outages

- February 15, 2022: Record of decision – Ontario Power Generation - Request for authorization to restart Pickering Nuclear Generating Station B Unit 5 following a forced outage

- December 1, 2021: Record of decision - Bruce Power Inc. – Request for authorization to restart Bruce Nuclear Generating Station A Unit 3 following its current planned outage

- November 24, 2021: Record of decision – Bruce Power and Ontario Power Generation - Review by the Commission of 3 designated officer orders Issued to Bruce Power and Ontario Power Generation Inc. on July 26–27, 2021; and requests to restart reactors subject to the orders

On this page

- CNSC staff’s approach to assessing safe operation of pressure tubes

- Inside the reactor

- How staff assess the safety of pressure tubes

- How the independent Commission makes a licensing decision on the safety of pressure tubes

- How the CNSC ensures that pressure tubes are safe to operate

- Pressure tube inspections

- Fitness for service programs

- Evaluation process

- Related links

CNSC staff’s approach to assessing safe operation of pressure tubes

The elevated Heq finding at the outlet end prohibited the use of traditional methods to complete the require fitness-for-service evaluations for the small region near the outlet end of the pressure tubes. Through detailed analysis, licensees demonstrated that there were no flaws of concern in the affected region in any of the inspected pressure tubes. Furthermore, when this information was extrapolated to the population of tubes that were not inspected, it was possible to demonstrate that the condition of the entire population of tubes in the affected reactor cores was acceptable.

A Commission hearing and 3 meetings were held between September 2021 and November 2022 to discuss the impact of these findings and the actions taken by industry. The Commission was satisfied that the fitness-for-service requirements were met and subsequently authorized Bruce Power and OPG to continue operation of the affected units, as the terms of the designated officer orders had been satisfied.

In March 2022, the Commission was also informed that additional testing of a Unit 6 pressure tube had revealed elevated Heq in a small region at the inlet end. As with the outlet region findings, traditional methods for evaluating pressure tube fitness for service could not be applied at the inlet end. However, the approach adopted to demonstrate fitness for service at the outlet end could not be applied to the inlet end, because flaws have been detected in the inlet region in some inspected pressure tubes. CNSC staff concluded that the risk to nuclear safety was not significant because there would be no impact on the ability of process and safety systems to mitigate the consequences of a pressure tube rupture, should one occur during reactor operation. An update was provided to the Commission in November 2022.

Industry has developed a research and development program to update predictive models and evaluation tools with the goal of returning to a traditional approach for the completion of fitness-for-service evaluations for pressure tubes operating beyond 210,000 EFPH. CNSC staff have also updated the preliminary risk assessment from March 2022 with a formal risk-informed decision making assessment.

The Commission has requested that licensees and CNSC provide regular updates to the Commission. The next update will be provided with the Regulatory Oversight Report for Nuclear Power Generating Sites: 2022 in fall of 2023.

Inside the reactor

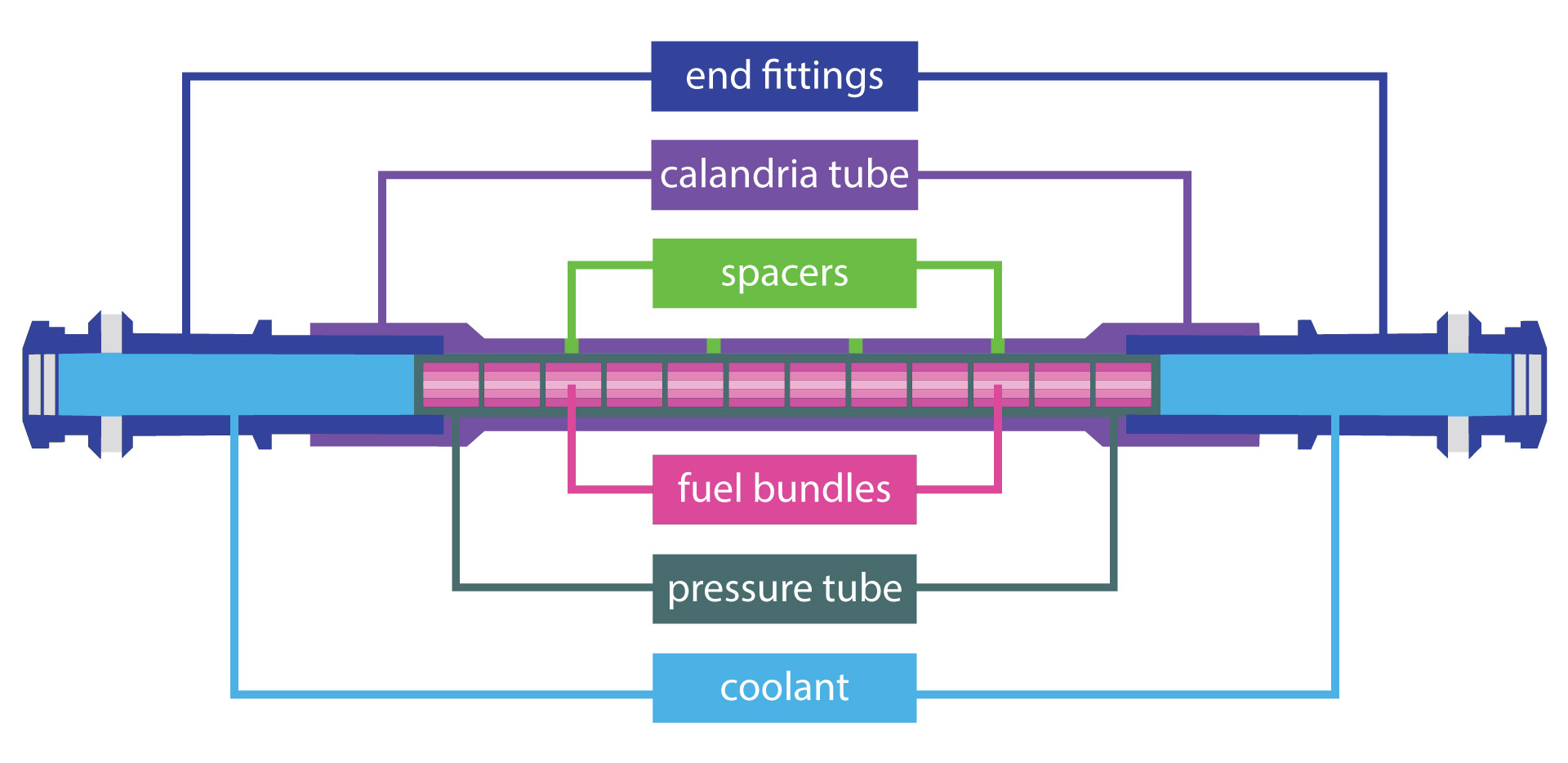

Inside all CANDU nuclear power reactors in Canada are several hundred fuel channels. Each fuel channel has 1 pressure tube, 1 calandria tube, end fittings and spacers.

Pressure tubes are the heart of the reactor. They are designed to contain the fuel bundles and the primary coolant (water) in a reactor. During regular nuclear power plant operation, pressure tubes are exposed to high temperatures, high pressure and intense radiation, which can cause them to deteriorate. Much like with any machine, over time, nuclear reactor parts need to be tested, serviced and replaced.

The CNSC licenses nuclear power plant operators, who are required to regularly monitor the condition of pressure tubes to ensure that they meet operational fitness standards. Key issues to watch for in pressure tubes are subtle changes in shape, state of material properties and appearance of flaws. These issues are monitored through periodic inspections and assessments by the licensee, followed by an independent review by the CNSC.

Although pressure tubes are deliberately designed to withstand operational wear and tear, they age over time, Therefore, aging management programs for pressure tubes are essential to the ongoing safe operation of nuclear power plants.

Licensees must understand the impact of aging on pressure tubes, through performing extensive research, testing and modelling development.

They are required to perform inspections and demonstrate to the CNSC’s satisfaction that pressure tubes are able to continue to operate safely into the future. Every 2 to 3 years, inspections on pressure tubes are carried out. Results are used by the licensees to conduct modelling and to predict the fitness for service of pressure tubes. Licensees must provide the CNSC with their periodic inspection plans.

The CNSC, as Canada’s nuclear regulator, ensures comprehensive and rigorous oversight. CNSC staff analyze and evaluate the data provided by the licensee to confirm pressure tubes meet operational standards.

Fuel Channel: Inside each CANDU nuclear power reactor in Canada are several hundred fuel channels. There are various parts that make up the fuel channel. On the 2 opposite ends of the pressure tube are end fittings. Inside the pressure tube are the fuel bundles (that generate heat) and coolant. On the outside of the pressure tube is the calandria tube, which is separated from the pressure tube by multiple spacers.

How staff assess the safety of pressure tubes

CNSC technical experts review and analyze data to draw conclusions on the current and projected safety of pressure tubes. If there is ever any question or outlying data, staff will formally ask the power plant operator (a CNSC licensee) to conduct further sampling work and/or impose a unit maintenance outage to inspect or replace pressure tubes in order to continue operating safely. One such case occurred in 2019 when the CNSC requested that Bruce Power take an additional outage to perform pressure tube inspection and maintenance for Unit 6. This was to ensure safe operation until the shutdown for the refurbishment outage in 2020.

Before staff make any licensing recommendations to the independent Commission, they make various requests to the licensee to validate the accuracy of the data presented from sampling pressure tubes.

How the independent Commission makes a licensing decision on the safety of pressure tubes

CNSC staff recommendations are presented in a Commission member document. This information, along with information presented from the licensee and intervenors, is thoroughly reviewed by Commission members and deliberated upon before the Commission issues a licensing decision.

How the CNSC ensures that pressure tubes are safe to operate

The data from regular pressure tube inspections is analyzed using various techniques to confirm the tubes are safe to operate for the conditions they were designed for.

During operation, flaws can form in the tubes because of contact with the fuel bundles or contact between the pressure tube and the calandria tube. The material will also undergo changes because of irradiation, exposure to the heavy water used to cool the fuel, and the absorption of deuterium (heavy hydrogen acquired from normal operation). These changes are expected as the result of aging of the pressure tubes from normal operation. Licensees must confirm that aged tubes continue to meet the required safety margins specified in the design documents and industry standards.

Licensees have technical experts who dedicate countless hours to reviewing and analyzing hundreds of data points using complex equations and predictive modelling to validate the integrity of pressure tubes. This work ensures that the pressure tubes continue to meet the required safety margins and that pressure tubes are aging in a predictable manner. Licensees are required to test pressure tubes periodically to collect new data for these evaluations.

Licensees develop their own strategies, reviewed and approved by the CNSC, to evaluate the fitness for service of pressure tubes for the duration of their operational life. Evaluations are typically completed 2 to 3 years depending on a reactor’s outage schedule. The evaluations are updated following each outage and more frequently if new information is obtained from research or regular operational activities that would affect the conclusions of an existing evaluation.

If a licensee determines that any pressure tubes cannot meet safety margins beyond a certain point in time, corrective actions must be taken before that time is reached. Such actions could include more frequent inspections, removing the fuel bundles from some channels, limiting the maximum power output of a reactor, replacing channels or, if necessary, shutting down the reactor. The specific corrective actions selected will depend on the finding’s potential risk to the safe operation of the pressure tubes.

There is a dedicated team of CNSC specialists and project officers who monitor the licensee’s activities related to pressure tube inspections and evaluations and provide updates to the Commission.

Pressure tube inspections

Pressure tube evaluations are generally divided into 2 categories:

- Evaluations for inspected pressure tubes

- Risk assessments to extrapolate the findings from inspected pressure tubes to make judgements about the condition of the entire population of tubes in a reactor core

Inspection programs attempt to identify tubes that are mostly likely to be susceptible to various forms of degradation. The evaluation of the inspection results for those tubes are considered representative of the uninspected population of tubes. Evaluations are carried out by extrapolating findings from the inspected pressure tubes to assess the likelihood of failure in the uninspected population. These evaluations are also used to determine if the sample of the tubes selected for inspection need to be increased as the pressure tubes continue to age.

In general, at least 30% of the pressure tubes in a reactor core will undergo inspection during the reactor’s lifetime to assess the tubes’ condition. The inspection scope for all reactor units currently exceeds the minimum periodic inspection program requirements established in CSA standard N285.4, which establishes the requirements for inspecting nuclear piping, pressure vessels and related components.

Fitness for service programs

Programs for fitness for service are made up of 4 key required elements:

- Licensee demonstration of an understanding of the degradation mechanisms that potentially impact pressure tubes; sources of information include research activities and operating experience

- Implementation of plans for research, inspection and examination of pressure tubes to adequately manage potential degradation mechanisms

- Inspections throughout the reactor’s operating life, and periodic removal of pressure tubes from service for examination

- CNSC staff review of licensee evaluation using the results of monitoring activities, to confirm that required safety margins for design and fitness for service are maintained; the results of these evaluations are also used to verify that the current understanding of the degradation mechanisms is correct

These 4 elements form a continuous feedback loop between the licensee and the CNSC throughout the operating life of the pressure tubes.

CNSC staff evaluate the overall program and accept it if it meets requirements. They also actively monitor licensee activities to ensure that compliance verification criteria are met.

Evaluation process

After every inspection campaign, inspected pressure tubes must be evaluated against compliance verification criteria to demonstrate that the tube will meet the established safety margins until at least the next planned inspection or, in some cases, the expected end of life.

For extended operation, licensees often state a maximum period of time expressed in equivalent full-power hours for pressure tube operation. For example, Darlington units are licensed to 235,000 equivalent full-power hours and Bruce Power units are licensed to 300,000 equivalent full-power hours. These limits only apply to pressure tubes that satisfy all fitness for service compliance verification criteria up to those limits. Through the execution of the fitness for service strategy, if it is determined that any tubes will not maintain the required safety margins up to the licensing limit, corrective actions will be required. As previously mentioned, this could include the following:

- Enhanced inspection activities to obtain data to improve evaluations

- Defuelling of channels to reduce degradation rates

- Replacement of pressure tubes that cannot meet required safety margins

Regardless of the length of the licence period for a given station, it is not permitted to operate pressure tubes that do not meet safety margins established in the compliance verification criteria. If corrective actions to resolve issues will not be effective or are impossible to implement, a reactor has to be shut down prior to the maximum operating limit specified in the licence.

Related links

- Pressure tubes: The heart of the reactor (video)

- Regulatory action

- External Advisory Committee on Pressure Tubes

- Ontario Power Generation: Application to renew the licence to prepare site for the Darlington New Nuclear project (DNNP)

- The CNSC’s response to the Globe and Mail related to pressure tubes

- The CNSC’s response to the Clean Air Alliance related to pressure tubes

- Remarks by President Rumina Velshi on recent public questions about pressure tubes at the Pickering Nuclear Generating Station

- Video of the remarks by President Rumina Velshi at the April 27, 2021 public Commission meeting